- Details

- Category: Quality

Since 1988 DAFRAM's Quality Management System has been certified as compliant to ISO 9001 requirement by accredited body RINA Services S.p.A. and it has been maintaind up to today. Quality Management System has been extended and improved by obtaining specific product certifications also to follow new technical and market needs.

In 2006 DAFRAM improved its Management System by including also environmental aspects on it and obtaining the ISO 14001 certification by accredited body RINA Services S.p.A..

At last in 2011 Company implemented a Health and Safety Management System certified as compliant to OHSAS 18001 requirements by accredited body RINA Services S.p.A..

Today the whole process of ball valves design, production and after-sales is covered by Management System that is certified and audited by accredited external bodies on the basis of timing defined by following standards of reference:

- ISO 9001 for ball valves design, production and after-sales

- ISO 45001 and ISO 14001 for the design, production and after-sales service of industrial ball valves through the following activities: bar cutting, machining, washing and pickling, welding, assembly, hydrostatic and pneumatic testing, sandblasting and coating, packing and delivery

- Product standard API Specification 6A

- Product standard API Specification 6D

- Product standard API Specification 6DSS

- ATEX Directive for equipments and protective systems intended for use in potentially explosive atmospheres

- PED Directive for pressure equipments

- EN 14141 - valves for transportation of natural gas in pipeline

- SIL 3 for Floating ball valves

- SIL 3 for Trunnion ball valves

- SIL 3 for Top Entry ball valves

- SIL 3 for Fully Welded ball valves

Download QHSE Policy

Slide certificati

ISO 9001

ISO 14001

Certificato sistema gestione qualità ISO 9001:2015

PROGETTAZIONE, PRODUZIONE ED ASSISTENZA POST-VENDITA DI VALVOLE PER USO INDUSTRIALE

Prima emissione: 27-06-1989

Scadenza: 04-11-2024ISO 14001

ISO 14001

Certificato sistema gestione ambientale ISO 14001:2015

PROGETTAZIONE, PRODUZIONE ED ASSISTENZA POST-VENDITA DI VALVOLE PER USO INDUSTRIALE, MEDIANTE LE FASI DI TAGLIO DELLE BARRE, LAVORAZIONE PER ASPORTAZIONE DI TRUCIOLO CON MACCHINE UTENSILI, LAVAGGIO E DECAPAGGIO, SALDATURA, ASSEMBLAGGIO, COLLAUDO IDROSTATICO E PNEUMATICO, SABBIATURA E VERNICIATURA, IMBALLAGGIO E SPEDIZIONE

Prima emissione: 28-11-2012

Scadenza: 24-11-2024ISO 45001

ISO 45001

Certificato Sistema di Gestione della Sicurezza e della Salute sul luogo di lavoro ISO 45001:2018

PROGETTAZIONE, PRODUZIONE ED ASSISTENZA POST-VENDITA DI VALVOLE PER USO INDUSTRIALE, MEDIANTE LE FASI DI TAGLIO DELLE BARRE, LAVORAZIONE PER ASPORTAZIONE DI TRUCIOLO CON MACCHINE UTENSILI, LAVAGGIO E DECAPAGGIO, SALDATURA, ASSEMBLAGGIO, COLLAUDO IDROSTATICO E PNEUMATICO, SABBIATURA E VERNICIATURA, IMBALLAGGIO E SPEDIZIONE

Prima emissione: 27-01-2011

Scadenza: 22-12-2025API 6A

API-6A

License Number: 6A-1175

Effective Date: 31-03-2024

Expiration Date: 31-03-2027API-6D

API-6D

License Number: 6D-0265

Effective Date: 31-03-2024

Expiration Date: 31-03-2027API6-DSS

API-6DSS

License Number: 6DSS-0029

Effective Date: 31-03-2024

Expiration Date: 31-03-2027ATEX

ATEX

Equipment or Protective System or Component intended for use in potentially explosive atmospheres

Date: 02-11-2011conform EN 14141

EN 14141

Product: Ball valves

Type: Fully welded valves, Bolted body valves

Date: 23-01-2024

Expiration Date: 22-01-2029http://www.dafram.it/images/slide/certificati/conformEN14141.jpg

PED

PED

Certificato di Approvazione del sistema di Qualità

VALVOLE A SFERA: Ball Valves Trunnion and Floating

Date: 12-01-2023

Expiration Date: 12-01-2026SIL Floating

SIL 2-Ways Floating Ball Valve

Compliance with the requirements of the standards IEC 61508 Parts 1-7:20210

Date: 28-04-2021

Expiration Date: 27-04-2024http://www.dafram.it/images/slide/certificati/sil-floating.jpg

SIL trunnion

SIL 2-Ways Bolted side entry trunnion mounted ball valve

Compliance with the requirements of the standards IEC 61508 Parts 1-7:20210

Date: 28-04-2021

Expiration Date: 27-04-2024http://www.dafram.it/images/slide/certificati/sil-trunnion.jpg

SIL top entry

SIL 2-Ways Bolted top entry trunnion mounted ball valve

Compliance with the requirements of the standards IEC 61508 Parts 1-7:20210

Date: 28-04-2021

Expiration Date: 27-04-2024http://www.dafram.it/images/slide/certificati/sil-topentry.jpg

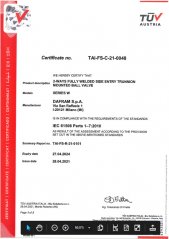

SIL fully welded

SIL 2-Ways Fully welded side entry trunnion mounted ball valve

Compliance with the requirements of the standards IEC 61508 Parts 1-7:20210

Date: 28-04-2021

Expiration Date: 27-04-2024http://www.dafram.it/images/slide/certificati/sil-fullywelded.jpg

- Details

- Category: Quality

According to written procedures the whole manufacturing process of ball valves is continuously monitored by the following inspections and tests performed during:

- Customer evaluation and monitoring

- Checking of raw incoming materials certification

- Inspection of manufacture of valve components

- Pressure tests

- Functional tests

- Non destructive tests

- Final inspection of finished valves

- Details

- Category: Quality

If specified by the purchaser, the following different tests can be berformed to verify valve properties and performances, to verify material chemical composition or mechanical properties, to qualify valves to special working conditions or to long working life:

VALVE TESTS

- Pressure test at high/low temperatures

- Low e and High pressure seat gas test in accordanc with Annex C of API 6D

- On customer request pressure tests can be performed in accordance with other standards like API 598 and EN 12266-1

- Anti static test

- Torque test. Torque value is verified during this test as well.

- Functional valve test or functional valve and actuator test.

- Fugitive emission test to ISO 15848 or to other standards

- Paint dry film thickness check

- Insulating coat testing by holiday detector ISOLTEST HD93

- Cavity relief test

- Cryogenic test down to minus 196 °C

- Strain gauge test

- Hyperbaric test

- API PR2 test

- Details

- Category: Quality

CERTIFICATIONS

Every DAFRAM valve identified by a univocal Serial Number, will be delivered complete with EN 10204 3.1 material certificate of pressure containing parts and 3.1 certificate of pressure tests. In addition, all other certificates concerning special valve tests, destructive or non destructive tests and qualification tests according to purchase order requirements will be included. On customer request a third part inspector can witness every test and issue a certificate in accordance with EN 10201 3.2.

NEWS

Access to this area to read the latest news and keep you informed on the activities of DAFRAM spa.

Access to this area to read the latest news and keep you informed on the activities of DAFRAM spa.

Read more...

CONTACTS

Address, maps, phone numbers, email contacts, LinkedIn.

Address, maps, phone numbers, email contacts, LinkedIn.

Read more...

DESIGN CHANGES

Because of the constant technical review of our products, we reserve the right to modify those products within the specified Standards criteria... Read more...

Because of the constant technical review of our products, we reserve the right to modify those products within the specified Standards criteria... Read more...