- Details

- Category: Construction

BODY

CONSTRUCTION.

Two or three pieces bolted body construction designed for maximum rigidity against pipeline forces. Bolted construction allows easy service and on site maintenance.

BODY SEALING.

A primary positive sealing action of O-rings and a secondary fire-proof graphite gasket assure no leakage in all static body joints.

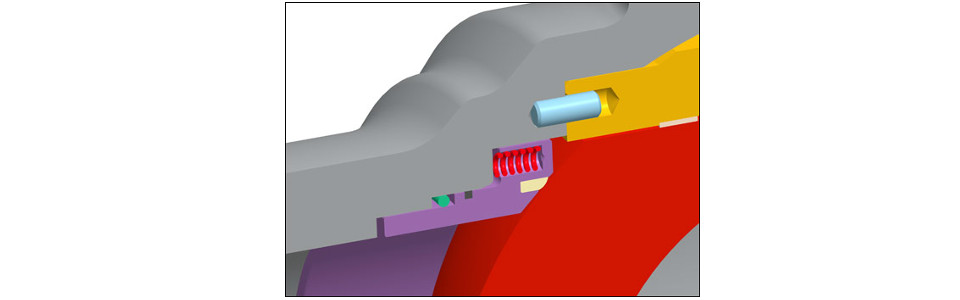

PRESSURE RELIEF (API 6D, 6.8).

All standard trunnion ball valves shall be provided with self relieving seats allowing automatic body cavity relief exceeding 1,33 times the valve pressure rating at 38°C.

DRAIN SYSTEM.

All Dafram trunnion mounted ball valves have a drilled and threaded drain connection as per API 6D.

BLEED VALVE.

All Dafram trunnion mounted ball valves have a threaded vent anti-blow-out valve as per API 6D.

VALVE ENDS (API 6D,6.7).

Standard end flanges shall be furnished in accordance with ASME B16.5 for sizes up to and including DN 600 (NPS 24), except MSS SP-44 for DN 550 (NPS 22) and ASME B16.47 Series A for DN 650 (NPS 26) and larger sizes. Standard welding ends shall conform to ASME B31.8 and ASME B16.25.

- Details

- Category: Construction

SEATS, SEAT INSERTS & SEAT SEALINGS

On request, two other Trunnion mounted valve designs are available:

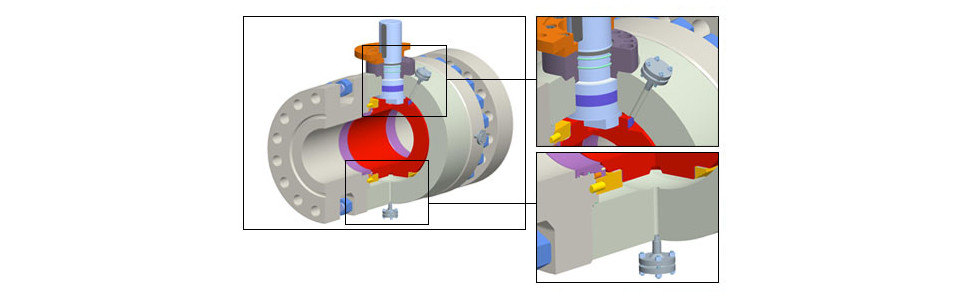

DOUBLE PISTON EFFECT DESIGN.

Bi-directional, twin seats valve (with two seats, both seats are bi-directional). This means valves designed for blocking the fluid in both downstream and upstream directions, with two seats, each sealing in both directions: from the valve ends to the valve body cavity and from the body cavity to the valve ends. This seats design improves the sealing capacity of the valve adding a seating surface in line, but an external safety relief valve is needed to allow the release of the cavity over-pressure.

DOUBLE BLOCK AND BLEED (DBB).

According to API 6D definition: valve with two seating surfaces which, in the closed position, blocks flow from both valve ends when the cavity between the seating surfaces is vented through a bleed connection provided on the body cavity.

UPSTREAM SELF RELIEVING DESIGN.

Uni-directional, twin-seat valve with the upstream seat uni-directional and the downstream seat bi-directional. This combination maintains the sealing capacity of the valve in the event of failure of the upstream seat. In addition, as the upstream seat automatically releases the body cavity over-pressure, no safety relief valve is needed for this purpose.

- Details

- Category: Construction

BODY

WELDED BODIES.

When maintenance is not required, fully welded valves with no leak paths through the body are available in a more safe solution.

TOP ENTRY BODIES.

When maintenance on line is required, top-entry ball valves are available. With the stem in vertical position this valve design permits disassembly, replacement of all internal parts and seals and reassembly without removing the valve from the line.

BODY SEALING.

For special service conditions (i.e. cryogenic, or high temperatures) O-rings can be replaced by alternative gaskets suitable for the service (e.g. lip seals). In valves working with gas on pressure Classes ≥ 600, the standard O-rings will be replaced with Anti Esplosive decompression (AED) ones.

NEWS

Access to this area to read the latest news and keep you informed on the activities of DAFRAM spa.

Access to this area to read the latest news and keep you informed on the activities of DAFRAM spa.

Read more...

CONTACTS

Address, maps, phone numbers, email contacts, LinkedIn.

Address, maps, phone numbers, email contacts, LinkedIn.

Read more...

DESIGN CHANGES

Because of the constant technical review of our products, we reserve the right to modify those products within the specified Standards criteria... Read more...

Because of the constant technical review of our products, we reserve the right to modify those products within the specified Standards criteria... Read more...